🧯 CO₂ Automatic Fire Suppression System

With Solenoid-Actuated Pilot Cylinder

Overview

The CO₂ Automatic Fire Suppression System is a proven, high-efficiency clean-agent fire protection solution widely used for more than 50 years in normally unoccupied, high-risk environments. The system extinguishes fire by rapid oxygen displacement and heat absorption, providing instant fire knockdown without residue or equipment damage.

CO₂ systems are ideal where flammable liquids, electrical hazards, or high-value machinery are present and water-based systems are unsuitable.

Key Features & Advantages

🔥 Extremely Fast Fire Suppression

• Fire control within seconds of discharge

🧼 Clean & Residue-Free

• No water, foam, or powder cleanup required

⚙️ Non-Corrosive & Equipment Safe

• Suitable for electrical panels, machinery, and metals

🧠 Multiple Activation Modes

• Automatic

• Electrical

• Manual

⏱️ Adjustable Discharge Delay (0–30 sec)

• Provides evacuation and safety warning time

🔌 Solenoid-Actuated Pilot Cylinder

• Reliable, precise, and remote-controlled activation

How the System Works

• CO₂ is stored as a liquefied gas in high-pressure cylinders at 57 bar (20°C)

• Upon activation, the solenoid pilot cylinder triggers the main cylinders

• Liquid CO₂ expands rapidly through the piping network

• Oxygen level is reduced from ~21% to below 15%, extinguishing the fire

• Heat absorption prevents re-ignition

• Discharge occurs through engineered nozzles for uniform flooding

⚠️ CO₂ systems are intended strictly for normally unoccupied areas and must include safety interlocks and warning devices.

Flow System – Standard Configuration

✔ Designed for external and variable environmental conditions

✔ Simple and reliable layout for single-zone or dedicated hazard protection

✔ Colorless, odorless, and non-contaminating extinguishing agent

✔ Suitable for industrial, electrical, and high-value machinery protection

System Technical Specifications

| Parameter | Details |

|---|---|

| Storage Cylinder Volume | 70 Liters |

| CO₂ Fill Weight | 45 kg |

| Storage Pressure | 57 bar |

| Max Cylinder Working Pressure | 124 bar |

| Discharge Pressure (20°C) | 60 bar |

| Main Power Supply | AC 220V / 50Hz |

| Standby Power Supply | DC 24V |

| Activation Methods | Automatic / Electrical / Manual |

| Activation Delay | 0–30 seconds (adjustable) |

| Pilot Cylinder | Solenoid-actuated |

| Operating Temperature | 0°C to 50°C |

| Humidity Tolerance | Up to 95% RH |

| Country of Origin | Made in China |

Complete System Components & Scope of Supply

Fire Detection & Control System

🖥️ CO₂ Fire Suppression Control Panel

• Microprocessor-based releasing panel

• Automatic & manual discharge logic

• Integrated alarm, delay, abort, and supervisory functions

🔥 Smoke Detectors

• High-sensitivity photoelectric / addressable type

🌡️ Heat Detectors

• Fixed temperature

🖐 Manual Call Point (MCP)

• Break-glass type for emergency activation

🔊 Sounder with Flash Beacon

• Audible & visual pre-discharge and discharge warning

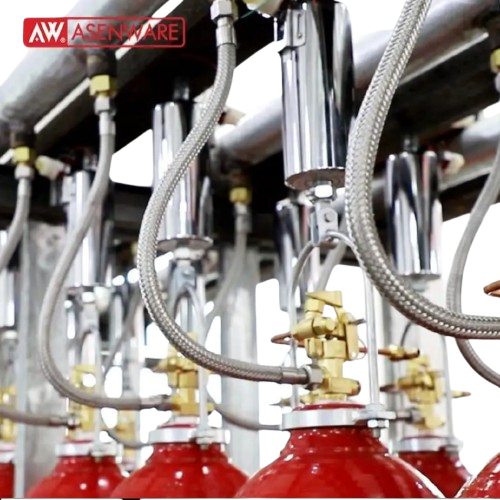

Suppression & Discharge Hardware

⚙️ CO₂ Storage & Release Assembly

• CO₂ storage cylinders

• Solenoid-actuated pilot cylinder

• Main discharge valves

• Syphon tubes

• Pressure gauges

• Flexible high-pressure hoses

• Engineered discharge nozzles

• Heavy-duty wall / floor mounting brackets

Piping & Network Infrastructure

🧱 MS Pipe Networking (Schedule-40)

• Seamless mild steel piping

• Designed as per CO₂ discharge calculations

• Includes all bends, fittings, reducers, and supports

• Surface painted / corrosion protected as required

Electrical Wiring Works

🔌 Complete System Wiring

• Fire-rated,cables

• Detection loops, releasing circuits, and control wiring

• Proper tagging, routing, and termination

Installation

🛠️ Installed by trained and certified technicians

🛠️ In accordance with approved drawings and standards

Testing & Commissioning

🧪 Functional testing of control panel and detectors

🧪 Pilot cylinder and main release mechanism testing

🧪 Alarm, delay timer, MCP, and abort switch verification

🧪 System integrity and operational validation